Product Description

Product Description

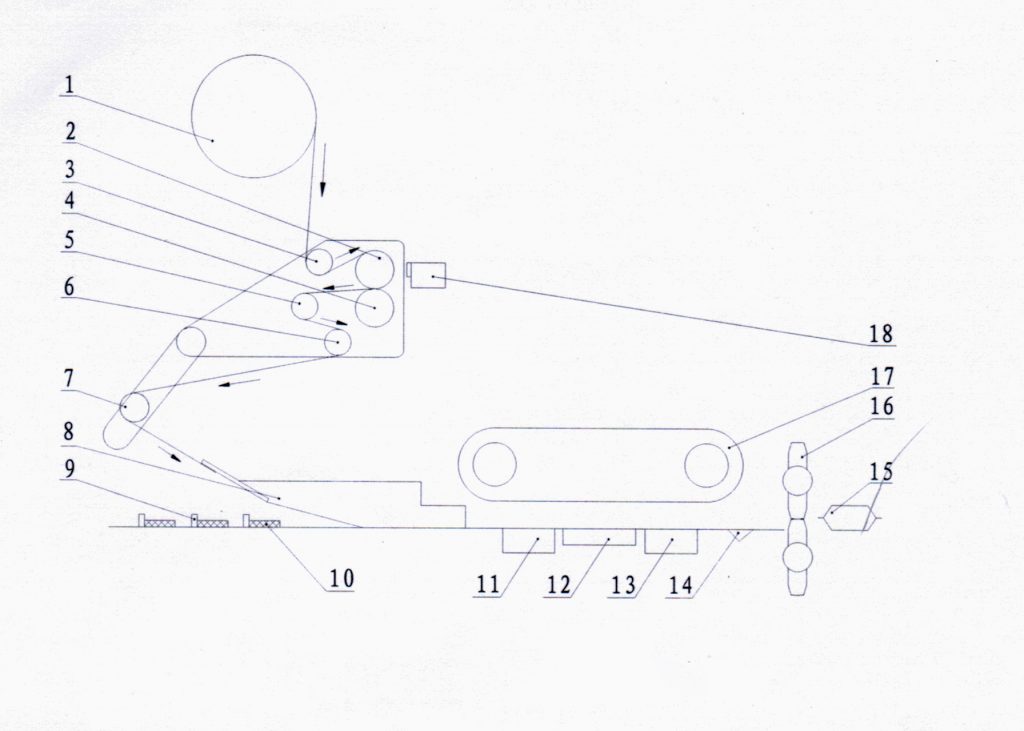

GF-300A Candy Pillow bag sealing Machine Show

Application

This machine is suitable for biscuits, bread, moon cake, pie, fruit pies, candy,and other solid regular objects packaging.

Product Features

1. Compact structure, stable performance, simple operation.

2. Dual frequency conversion control, bag length cutting, without air conditioning, in one step, saving time and film.

3. Imported appliances, touch interface, convenient parameter setting.

4. Self-diagnostic function, clear failure display.

5. High sensitivity photoelectric eye tracking, which makes the sealing and cutting more accurate.

6. Temperature independent PID control, and better suited to a variety of materials coated.

7. Positioned stop function, without sticking knife fees film.

8. Turn the system simple, more reliable, and easier maintenance.

9. All the controls are achieved by software, convenient for function adjusting and technical upgrade, never backward.

Main Technical Parameters

| Bags size | L: 65~190mm |

| W: 30~110mm | |

| H: 5~40mm | |

| Longitudinal and transverse sealing sealing strength | >15N/mm² |

| Packing speed | 40~230Bags/min |

| Packaging film width | 80~300mm |

| Power Specifications | 220V 50/60Hz 2.4KW |

| G.W. | 800kg |

| Dimensions | 3780*640*1560mm |

Details of sample usage

Equipment details

Put package 10 into the pushing chain track 9, entering into shaper 8. With the transmission of the feeding paper parts 1, 2, 3, 4, 5, 6, 7, the package paper is sent continuously and accurately into shaper 8. The package paper crosses the package material in the shaper through the act of shaper, making the package material in the shaper through the act of shaper, making the package paper pack on the article, and while the sending wheel 11 with brush 17 forward sends material, after being heated by heating copper 13 to make the vertical sealing complete. They continue going on forward through guide block 14, enter into the horizontal sealing cutter 16 to cut off the horizontal sealing, than finished go our product 15.

The dynamic of transmission system is driven through several transmission units to rubber roller through the double chain wheel, and finally complete feeding paper.

Feeding wheel catches piping package material carrial carried out by the shaper. And they are sent to vertical sealing roll wheel to finish its vertical hot mixing after being heated by heating copper and the hair brushes, vertical sealing hemming-stitch pressure flat. The horizontal sealing xdissors turn to the vertical heat mixed package materials that have been heated form a cross sealing through horizontal sealing head and vertical sealing line. Then they are cutted off at the same time through the relative motion of cutting tools and hammer anvil to send out from the terminal.

The above description uses DXD300 as an example, other models of machines are similar.

FAQ

Q1: Are you a trading company or manufacture?

A1: GF is a professional trading company with some experience manufacturers over years. Your order will be controlled from very beginning to the last.

Q2: What is your delivery time?

A2: Normally 30-45 days upon order confirmation.

Q3: What is your packing pattern?

A3: Special export wooden packing

Q4: How about your service?

A4: Engineers available to service machinery overseas

Q5: How about your product?

A5: We have the standard production and complete quality control system to ensure high quality

products. Our products get ISO. CE. SGS. IAF

Q6: How to choose the machine type for our bags?

A6: Pls support us the following information about the bag and the food.

1) bag pattern

2) bag size

3) the filling weight or volume

4) material of food: powder/liquid/paste/granular/massiveness

5) sample bags or pictures

Support

1. Round the Clock Customer Service Centers

2. Skilled Maintenance Team, Engineers Available to Service Machinery Overseas.

3. Expert Team, Technical Support

4. Abundant Spare Parts, Swift Storage Center

Tags: