Product Description

Product Description

GF8-200V Bag given Vacuum Packing Machine Show

GF8-200V Bag given Vacuum Packing Machine Description

Wide range of packaging: suitable for all kinds of shapes, States, properties of particles and blocks;

The rotary full-automatic bag feeding vacuum packaging machine is composed of two separate rotary bodies (filling system and vacuum system respectively)

It is suitable for different types of packing bags;

Easy to operate, PLC control, human-machine interface operation system, make the operation intuitive and convenient;

Easy to adjust and change varieties within 5 minutes

High degree of automation, unmanned in the whole process of weighing and packaging, automatic alarm in case of failure;

The perfect prevention system can intelligently detect whether the bag is opened and whether the bag is complete. If the material is not properly added, it will not heat seal, no waste the bag and material and save the cost;

Stainless steel materials are used for the packaging parts of the machine to ensure the health and safety of the materials and meet GMP standards;

Some components are equipped with imported tolerance plastic bearings, which do not need oil to reduce the pollution of materials;

Adopt oil-free vacuum pump to avoid polluting the production environment;

The use of pre-made bags, high sealing quality, improve the quality of finished products;

Easy to clean, the vacuum room can be cleaned;

High vacuum, up to 5mbar;Carbon brush heating mode, high stability;

The heat seal adopts imported heating plate, with long service life;

The machine has high stability, simple and reasonable structure, light loading afford and low failure rate;

Independent vacuum, double station twice vacuum, guarantee vacuum degree.

Main Technical Parameters:

| Name | Vacuum packing machine |

| Material of equipment | 304 stainless steel shall be used for contact with food, and other parts shall be in accordance with national food equipment regulations |

| Pneumatic components | Airtac ,SMC |

| Vacuum pump | Zhongde, Pu Xu |

| Driving mode | Frequency control motor drive and servo motor drive |

| Measurement mode | Shrinking cup feeder |

| Operation interface | Touch screen (Bilingual) |

| Applicable packaging material range | Dried bean, konjac, duck meat, pickled mustard and so on |

| Bag type | Stand up bag, handbag, zipper bag, four side sealed bag, three side sealed bag, paper bag and other composite bags |

| Packing bag material | Aluminum foil bag, composite flat bag, PE bag |

| Packing bag specification | Width: 60-150 mm length: 100-240 mm |

| Working flow | 1. feed bag 2. Open bag 3. fill 4. Add liquid 5. Reserve 6. Reserve 7. Output to vacuum room 8. Empty (according to customer’s product) |

| Filling range | 10 ~ 500g |

| Packing speed | 50-55 bags / m(speed depends on product characteristics and filling weight) |

| Accuracy | +2g |

| Pass rate | More than 99% |

| weight | 2500kgs |

| power | 8-10kw |

| Driving power supply | 380V, three-phase, five wire, 50Hz |

| Control power supply | DC24V |

| Outer size | 1450mm × 2450mm × 2000mm |

| Compressed air | ≥ 0.5m3/min (compressed air provided by the user) |

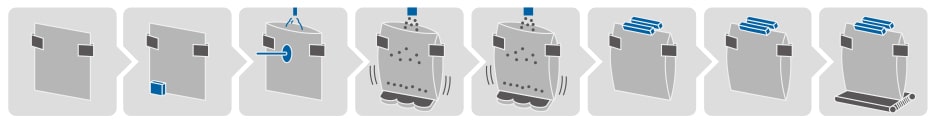

Working Process

Giving Bag —— Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table.

Date Printing —— According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

Opening Bag —— While the suction cup opens the opening of the packaging bag, air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

Filling & Consolidate 1 —— According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

Reserve

Reserve

Reserve

Bag straightening —— Straighten the bag and check whether there are materials in the bag at the same time. If there is no material in the packaging bag, it will not be transferred into the vacuum chamber.

Transfer —— The transfer manipulator between the two turntables transfers the packaging bags from the bag feeding turntable to the vacuum turntable. The packaging bag with the mouth of the packaging bag not opened or without materials added will not be passed into the vacuum chamber, and the packaging bag can be recycled and used again after it is dropped at this station.

Reserve

Transfer —— The packaging bag is transferred from the bag feeding turntable to the vacuum turntable, and the packaging bag enters the vacuum chamber.

Vacuum Chamber Cover —— The vacuum chamber is closed, and the vacuum in the vacuum chamber that has been sealed is recovered.

Semi-vacuum —— Evacuate most of the air into a semi-vacuum state.

First Vacuum —— Evacuate all the air, there are only a few bubbles in the bag.

Second Vacuum —— Pump the air bubble into a full vacuum state.

Third Vacuum —— Further into the vacuum state.

Sealing —— The sealing cylinder extends, and the sealing electric heating plate is energized to generate heat, Sealing bag.

Cooling Exhaust —— The sealing electric heating piece is cut off, and the cooling water cools the bag mouth to normal temperature.

The vacuum chamber is connected to the atmosphere, and the atmosphere enters the vacuum chamber.

Uncover and Move Out —— The vacuum chamber is opened, and the packaged product falls onto the finished product conveyor belt.

FAQ

Q1: Are you a trading company or manufacture?

A1: GF is a professional trading company with some experience manufacturers over years. Your order will be controlled from very beginning to the last.

Q2: What is your delivery time?

A2: Normally 30-45 days upon order confirmation.

Q3: What is your packing pattern?

A3: Special export wooden packing

Q4: How about your service?

A4: Engineers available to service machinery overseas

Q5: How about your product?

A5: We have the standard production and complete quality control system to ensure high quality

products. Our products get ISO. CE. SGS. IAF

Q6: How to choose the machine type for our bags?

A6: Pls support us the following information about the bag and the food.

1) bag pattern

2) bag size

3) the filling weight or volume

4) material of food: powder/liquid/paste/granular/massiveness

5) sample bags or pictures

Support

1. Round the Clock Customer Service Centers

2. Skilled Maintenance Team, Engineers Available to Service Machinery Overseas.

3. Expert Team, Technical Support

4. Abundant Spare Parts, Swift Storage Center

Tags: